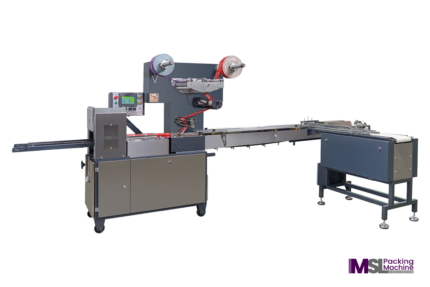

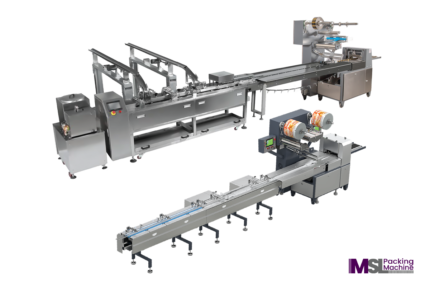

90-degree feeder

MSL Machine manufacturing 90-degree feeder is done according to the type of line and the size of the production hall with the PM25 packaging machine. This feeder is used to automate and speed up production lines. 90-degree feeders have a variety of features such as:

- Fault finding and alarm system for any kind of electrical and mechanical problems

- Ability to install Servo motor and normal motor

- *Feeders can be made for production lines of all kinds of chocolate, soap, Choco roll, Halva, etc.

Automatic Bakery packaging machine

This machine is ideal for packing apple pies, muffins, cakes, soft bread, and other regular-shaped products.

Key Features:

- Supports Servo & Standard Motors

- 220V Input Voltage

- SUS304 Stainless Steel & PU Conveyor

- Easy Cleaning & Maintenance

- Quick Size Adjustment for Different Products

- Smart PLC & Powerful HMI

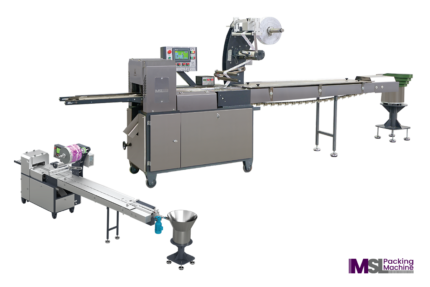

Automatic Sugar Cube Packing Machine

The automatic sugar cube packing machine eliminates the need for manual intervention, ensuring high-speed and precise packaging. This fully automated system allows you to bulk-load sugar cubes into the feeder, where they are then aligned in uniform rows on the packaging line and efficiently packed into single or twin packs. By incorporating this advanced packaging automation, you can reduce production costs while delivering your product to the market with premium, neatly arranged packaging that preserves its original quality, ultimately enhancing customer satisfaction. Additionally, this packaging line is compatible with both servo motors and standard motors, providing flexibility in operation.

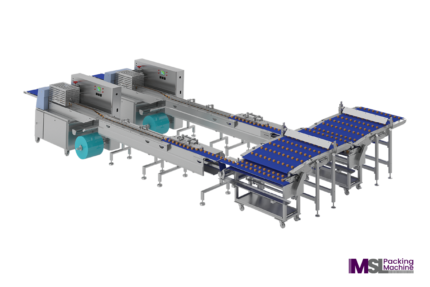

Automatic tray loading packaging line

Automatic tray loading packaging line is used for automatic lines with high output to pack single and double products such as biscuits and cakes along with the container. The function of this packaging machine is that the machine receives the product from the cooling tower and simultaneously places the containers under the product so that the product is automatically placed inside the container and transferred to the packaging area. This device has a smart PLC control and a touch screen that makes the human-machine interface completely easy so that even the most novice operators can change products with different specifications. The material used in the conveyor belt is PU, which is suitable for packing all kinds of food. It is also possible to provide this device with a servo motor system and a normal motor.

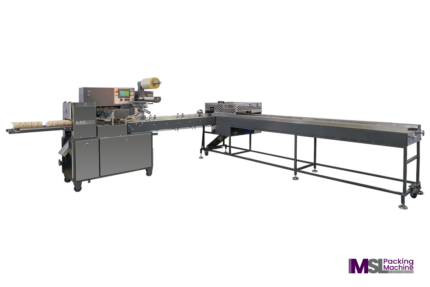

Chocoroll packaging and automation line for hard products

This machine is suitable for packing all kinds of chocorolls, rice bar, marshmallows, outmeal chocolate and products in a regular and hard shape. This packaging machine has a variety of features such as:

- Ability to install servo motor and normal motor

- It packs products with minimal product and cellophane waste.

- It has a simple structure, easy cleaning and maintenance, saving time and money

- Equipped with PU food antimicrobial safety tape

- Smart plc, touch screen, and powerful HMI

- Input voltage 220 volts

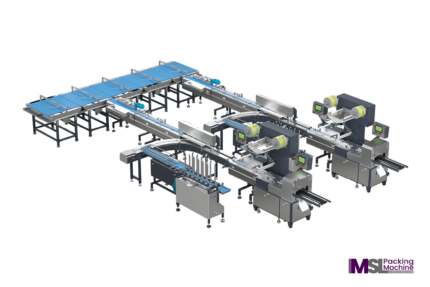

Cream Spreading packaging and automation line

The fully automatic MSL packaging machine can be installed on all single-line, double-line, new, and stock creamers. Installing the creamer on the machine eliminates the operator and thus reduces production costs. Therefore, it gives you the possibility to pack the biscuits in addition to a singular, in double, four, six, and eight number at a very high speed and luanch it to the market with the lowest production cost. In addition, MSL Machine Manufacturing's fully automatic on-edge lines have the ability to synchronize with all cream-spreading lines and allow you to pack cream biscuits in the form of sandwiches. Another advantage of this machine is the possibility of installing a Servo motor and a normal motor.

Cutlery pack packaging machine

Main Functions of the Machine:

- Intuitive touch screen interface for seamless adjustments and precise three-side sealing.

- Compatible with both servo and standard motors.

- Equipped with an advanced PLC controller and high-precision detection system ensuring exceptional accuracy and precise calculations.

- Fully automated operation, capable of detecting and adjusting length without manual intervention.

- Wide speed and length range with unrestricted speed adjustment.

Double-line Automation of paired products

The double-line automation has a special ability to pair and return products such as cookies, biscuits, crackers, and other objects with a regular shape. It also includes the possibility of packing your manufactured products in double or multiple quantities without any manual intervention at a very high speed, and it is easily possible to synchronize with your production line. In addition to automatically rotating products at high speed, this device minimizes waste with a uniform speed in transferring cookies to the packaging line and your product reaches the consumer without any manual intervention. It is also possible to install with a Servo motor system and a normal motor. The control system of this machine uses high-quality electronic intelligent PLC, touch screen, and high-quality HMI, which makes the operation of the packaging machine more convenient.

High speed chocolate packaging and automation line

This machine is used to package chocolate, cookies, and other products with a regular shape. It has the ability to connect to previous production lines using manual and automatic feeders, this device has a variety of features such as:

- Easier and faster adjustment of the machine when changing the size of products with different sizes

- It has a simple structure, easy cleaning and maintenance, saving time and money

- Equipped with PU food antimicrobial safety tape

- Ability to install servo motor and normal motor

- It has high-quality electrical components including smart PLC, touch screen

- Input voltage 220 volts

layered cake packaging and automation line

The fully automatic layered cake packaging line is designed to pack all kinds of roulette, Titops, etc. This machine has a variety of features such as:

- Equipped with an automatic leveling machine

- Ability to install servo motor and normal motor

- It has high-quality electrical components including smart PLC, touchscreen

- It has a simple structure, easy cleaning and maintenance

- Easier and faster adjustment of the machine when changing the size of products with different sizes

- Input voltage 220 volts

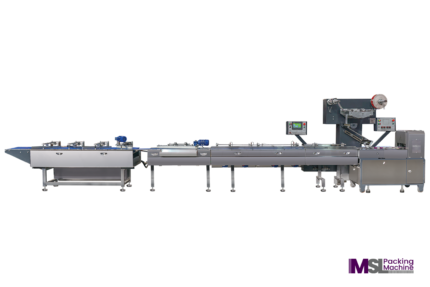

Linear wafer automation

MSL Machine manufacturing Linear feeder is done according to the type of line and the size of the production hall with the PM40 packaging machine. This feeder can be used to pack multiple wafers. This feeder has a variety of features such as:

- Fault finding and alarm system for any kind of electrical and mechanical problems

- Ability to install Servo motor and normal motor

- * Feeders can be ordered and manufactured for all kinds of wafer production lines.

Sandwich Biscuit packaging line (On-Edge)

The Sandwich Biscuit packing machine is suitable for all kinds of products such as dry biscuits, cream sandwich biscuits, all kinds of rice cakes, and products with sandwich packages. This machine also has the ability to install a creamer and can also pack creamed biscuits in the form of a sandwich. It also can install servo motor and normal motor.